Fundamentals of Twin-Screw Extrusion

Scale up: The Bump in the Road Between Development and Commercialization

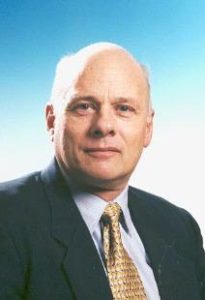

Paul Andersen

Coperion

Scale-up from lab to production is generally not the primary focus of the material scientist working on a new formulation with enhanced “properties”. Scale-up is often times not the primary focus of the development engineer charged with successfully compounding the new formulation. Scale-up is the headache of the production engineer who has to process the newly developed product successfully at commercially viable rates. Even though traditional guidelines such as scale-up factor based on power (Kw of commercial unit divided by Kw of development unit) or volume (production unit diameter cubed divided by the lab/development unit diameter cubed) indicate sufficient rate is achievable on the commercial unit, there are many pitfalls that can detour the path to success. These can include elevated material discharge temperature due to reduced heat transfer on the commercial unit as compared to the lab unit, feed limitations due to insufficient conveying efficiency of the feedstock on the commercial unit, particle entrainment resulting in vent blockage due to increased vapor velocity, and product quality issues due to less efficient stress transfer through the melted matrix material. This presentation will review these and other “bumps in the road” and discuss ways to minimize the probability that they will impact your success.

Biography – Paul Andersen

Director of Process Technology for Coperion Corporation, Ramsey, NJ. He is responsible for Process Engineering and New Technology Development for Twin Screw Extrusion/Compounding. He has almost 40 years of industrial experience and holds several patents related to Twin-screw compounding. Primary areas of technical experience have been reactive compounding, and devolatilization. Additionally he has worked extensively on compounding of multi phase engineering polymers, including nanocomposites and fiber reinforced materials. More recently the focus of his work has been on processing bio-materials.

Director of Process Technology for Coperion Corporation, Ramsey, NJ. He is responsible for Process Engineering and New Technology Development for Twin Screw Extrusion/Compounding. He has almost 40 years of industrial experience and holds several patents related to Twin-screw compounding. Primary areas of technical experience have been reactive compounding, and devolatilization. Additionally he has worked extensively on compounding of multi phase engineering polymers, including nanocomposites and fiber reinforced materials. More recently the focus of his work has been on processing bio-materials.

Paul earned a BS in Theoretical & Applied Mechanics from Cornell University and Ph.D. in Materials Science from Northwestern.

Paul is a past-president (2009-’10) of the Society of Plastics Engineers. He served on the Executive Committee from 2004 – 2011. Additionally, he has been an active member of the SPE Extrusion Division Board of Directors since 1990.

Paul also serves on the Editorial Board of Advances in Polymer Technology, and is a member of the Board of Trustees for the Polymer Processing Institute.

He has authored many technical papers for conferences, served as technical consultant for the SPE Twin-screw Extrusion educational video and wrote the chapter on Twin-screw Extrusion for the SPE Plastics Technician Toolbox.

Additionally Paul has authored papers for several journals as well as several book chapters. These include Mixing Practices in Co-rotating Twin-Screw Extruders in “Mixing and Compounding of Polymers” edited by Manas & Tadmor; The Werner & Pfleiderer Twin-Screw Co-Rotating Extruder System in “Plastics Compounding” edited by Todd, Twin-screw Extrusion in the 2006 edition of “Encyclopedia of Chemical Processing”, and Compounding Layered Silicate Nanocomposites in “Polymer Nanocomposites Handbook” edited by Gupta, Kennel and Kim.